Every fleet manager seeks ways to improve communication between the field and shop. With one of Equipment360’s premier features, users of the software can quickly get notified of field maintenance requests and have them instantly turned into work orders. Even better, everyone has real-time visibility on the progress of each individual work order.

A Time-Saving App to Enhance Your Fleet

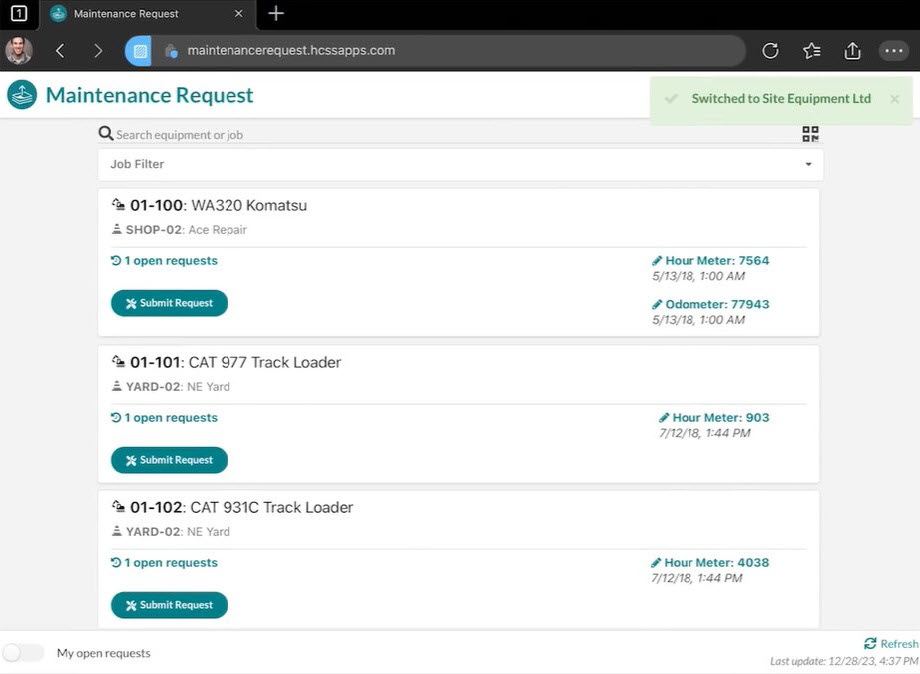

One of many prominent benefits in Equipment 360 is maintenance requests, which offer the ability to drastically reduce equipment downtime by letting your operators, foremen, and field mechanics submit equipment issues from anywhere at a moment’s notice.

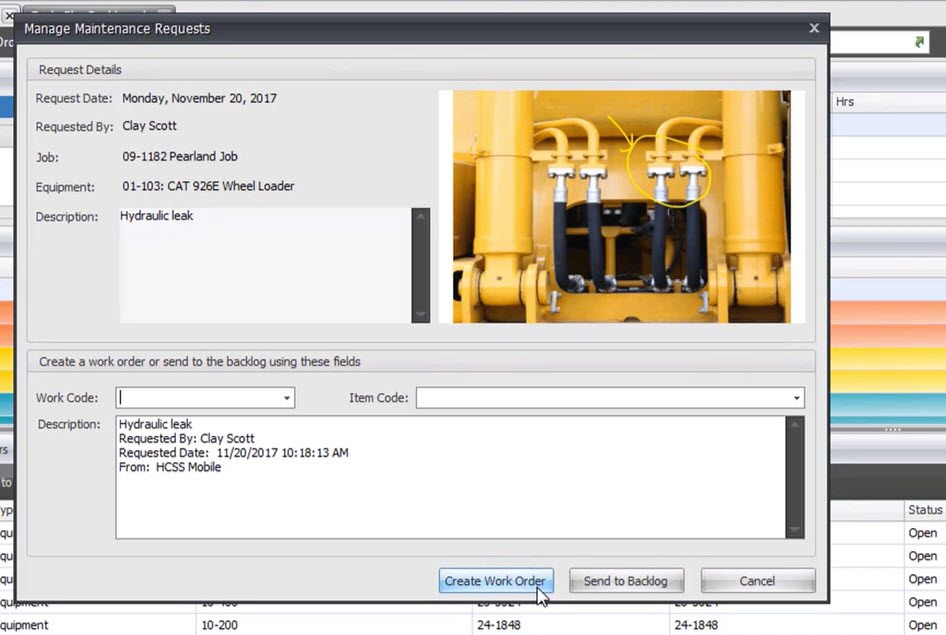

After selecting the job you’re in while using the app, you can single out any piece of equipment that’s experiencing an issue and quickly type what the problem or need is (in the example shown believe, there is a hydraulic leak, which has been clearly outlined). After hitting send on the request, shop managers are promptly alerted.

Moving on to the dashboard, the issue submitted is clearly visible. By double-clicking the request, it’s turned into a work order, which automatically has all of the information right there and can be assigned to a mechanic. In the short span of just a few minutes, equipment issues in the field are captured, submitted as an alert, and turned into an official work order queued for completion.

A process this simple creates an effective field-to-office feedback loop, ramping up direct communication between jobsites and the shop. There is no better way for fleet supervisors to ensure transparency across the organization on the status of work orders, ultimately helping to improve working conditions and spread out the workload, making maintenance planned.

Equipment Managers Love Using Equipment360

If you don’t want to take HCSS at their word regarding how effective Equipment360 is, just ask any of the customers directly.

For example, DXI Construction is a site preparation contractor in Churchville, Maryland that relies heavily on their massive fleet of equipment to complete jobs everywhere between Baltimore and Philadelphia and beyond, including Virginia, New Jersey, Delaware, and West Virginia.

Their Equipment Manager is longtime HCSS champion Chris Dixon, who adopted Equipment360 soon after the field-friendly app hit the market.

“I was real happy when Equipment360 was released because over the years, I had tried everything from Excel spreadsheets that I developed on my own to trying different standalone equipment maintenance software offerings,” Dixon said. “The big issue was that even if they were able to help me, there was always a disconnect between a lot of the processes that other HCSS products were already more or less serving in our company.”

With operators on various jobsites running so many pieces of equipment, it’s impossible to expect a fleet to keep on running indefinitely without proper care and attention.

“Utilization [is] ultimately tied into the maintenance,” Dixon continued. “There’s going to be a need for maintenance on [every] piece of equipment. It would be helpful for us to be able to take this information and put it in a maintenance package, and that’s exactly what Equipment360 was. It enabled us to move away from independent maintenance software and capture a lot of the processes of trying to collect meter readings or job locations.”

Pro Tip: Connect Equipment360 to the Full HCSS Platform

While Equipment360 is a phenomenal tool for knocking out equipment inspections, automating work orders, and getting preventive maintenance alerts, the software pairs extremely well with both HCSS Telematics (especially for GPS tracking) and HCSS Safety (a great way to get reminders about inspections, as well as record meetings and observations that help protect you and your crew).

“The core product serves the very initial needs of, ‘Where is my equipment and when does it need to be serviced?’ but we know there’s going to be a need in the future,” added Chris Dixon. “That’s part of another thing I’ve seen, is that all these products are always evolving. Utilization is now coming into E360 through the other products. That’s one of the great things I’m really appreciative about.”

Make It Easy On Your Equipment Managers

Keeping the operations of a fleet smooth and profitable is by no means an easy task. However, with the right software, much of the burden can be alleviated. Take better control of maintenance requests with enhanced field-to-office communication, and your company will never look back.

Your custom demo awaits. As the first step to reaping these benefits, schedule an Equipment360 demo now!