Construction has long been one of the most hazardous industries in the United States, and new OSHA regulations in 2025 only raise the stakes of safety compliance. With construction still accounting for more than one in five workplace deaths, compliance is no longer a background task; it is a frontline business priority. For contractors, safety managers, and project leaders, keeping up with evolving OSHA standards can feel overwhelming. Yet the risks of falling behind, ranging from employee harm and costly fines to reputational damage, make proactive safety planning essential.

The difference between an inspection that validates your program and one that exposes its weaknesses increasingly comes down to documentation.

OSHA’s Changing Landscape

This year’s regulatory updates reflect a deeper cultural shift in how OSHA approaches safety oversight. Rather than focusing only on violations after accidents occur, inspectors are now prioritizing proactive prevention and real-time verification. Wearables, smart helmets, and geo-fencing technologies are gaining recognition as valid compliance tools, making safety monitoring a continuous process rather than a box to check when convenient.

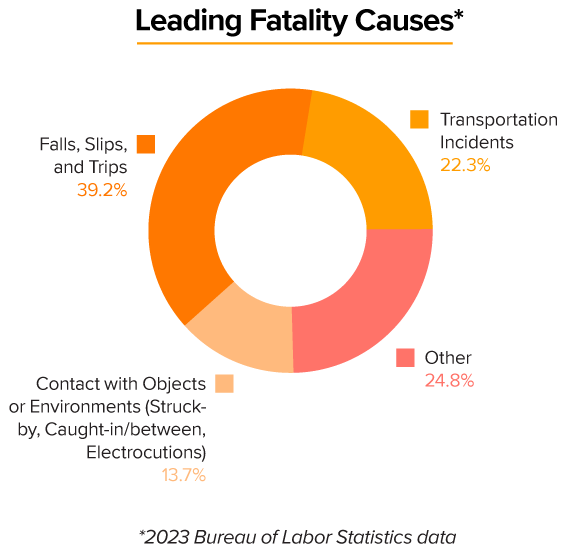

Falls, which remain the leading cause of construction fatalities, are now being regulated at even lower heights, requiring guardrails and tethering between six and ten feet. Employers in hotter regions must adopt comprehensive heat illness prevention programs, which include providing hydration, shaded rest areas, and documented recovery cycles. And before high-risk work, such as excavation or steel erection, begins, crews must complete and document a hazard analysis to prove risks have been evaluated and mitigated.

Taken together, these shifts underscore OSHA’s expectation that safety will be embedded into daily operations, offering a baseline of safety rather than just reactionary measures after an incident occurs. For safety managers, this means their role is not limited to compliance; it must now also extend to planning, educating, and ensuring that every worker has the necessary resources and documentation to demonstrate adherence. The result is a new standard where reliable OSHA recordkeeping software is not only helpful but increasingly central to meeting compliance requirements.

The Expanding Fatal Four and the Cost of Non-Compliance

For years, OSHA emphasized the “Fatal Four” hazards: falls, struck-by incidents, electrocutions, and caught-in or between events. In 2025, there has also been a growing awareness to acknowledge suicide, recognizing the mounting mental health crisis within the construction industry. The numbers highlight the severity: over 5,000 construction workers died by suicide in 2020, far surpassing fatalities from traditional jobsite accidents. OSHA’s decision to incorporate this issue into its core focus signals that safety compliance is no longer limited to physical hazards alone. Companies are now expected to approach worker protection more holistically, documenting not just accident prevention measures but also programs and practices that address well-being.

This mental health focus underscores the importance of proactive recordkeeping.

Inspectors are prioritizing evidence that employers are identifying risks, implementing prevention strategies, and training crews across all aspects of safety, including heat illness, fall prevention, and increasingly, mental health awareness. Toolbox talks, safety meetings, and training logs serve as proof points that a company is not only aware of OSHA’s scope but is actively fostering a culture that reduces risks of all kinds. By cataloging these efforts and making them easily retrievable, companies demonstrate compliance while also signaling to employees that their physical and mental health are equally valued. In a competitive work environment where it’s difficult to combat the labor shortage, construction companies that place an emphasis on mental health are at an advantage.

At the same time, OSHA has raised penalties again in 2025. Serious violations now carry fines of more than $16,500, and repeated or willful violations exceed $165,000. Beyond the dollar amounts, repeated infractions can trigger shutdowns, criminal referrals, or the loss of contracts, effectively grinding projects to a halt. For companies operating on thin margins and facing stiff competition, even a single citation can send ripple effects through budgets, schedules, and client relationships.

In addition to being a legal requirement, compliance is also a strategy for preserving stability, protecting reputation, and securing long-term profitability.

Documentation as Defense

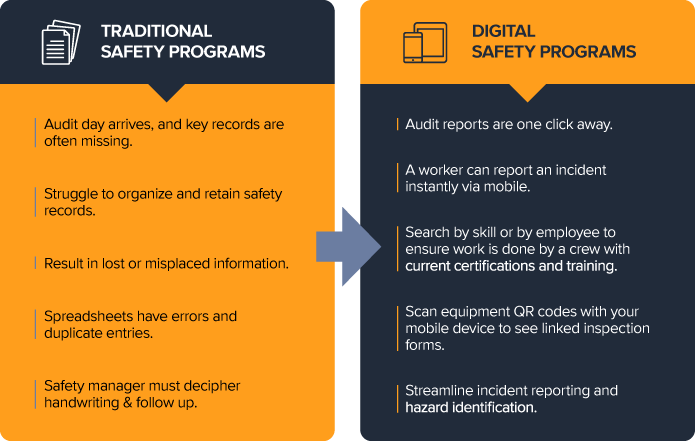

When inspectors arrive, they expect to see evidence of safety planning and enforcement. That often means training logs, safety meeting attendance, hazard analyses, incident reports, and enforcement actions, all produced on short notice. Companies still relying on paper systems often struggle here. Records get lost, handwriting goes unreadable, and key documentation is buried under layers of binders and spreadsheets. Even when forms exist, organizing them for an inspection can take weeks.

The story of McInnis Construction highlights the importance of documentation. After a worker fell 35 feet, the company faced the scrutiny of an OSHA investigation. Their safety manager, instead of scrambling, quickly generated a comprehensive report showing the worker’s entire training history, toolbox talks, and meeting attendance. By handing over the documents the next morning, he impressed the inspector, who remarked that such records usually take weeks to compile, if they exist at all. Ultimately, OSHA found no basis for issuing a citation. McInnis avoided fines and reputational damage, and the outcome underscored a critical truth: robust documentation does not simply satisfy auditors; it protects companies when accidents happen.

For organizations evaluating OSHA recordkeeping software, the lesson is clear: the ability to instantly produce reliable records is no longer a nice-to-have; it is a core compliance requirement.

The Critical Role of OSHA Recordkeeping Software

This is where digital solutions such as HCSS Safety have become indispensable. Rather than chasing signatures across jobsites or waiting for paperwork to make its way back to the office, safety managers can log observations, inspections, toolbox talks, and incidents directly from the field on a tablet or phone. Records are time-stamped, securely stored, and instantly retrievable, which transforms audits from stressful marathons into routine tasks. In practice, this means an OSHA 300 log can be generated in minutes, a supervisor can verify a worker’s certification on the spot, or a safety manager can review near-miss trends to adjust protocols before an accident occurs.

These capabilities are more than conveniences; they represent best practices for any organization seeking OSHA recordkeeping software.

Instant data retrieval ensures audit readiness, mobile entry increases accuracy, and integrated dashboards give leaders visibility across multiple jobsites. HCSS Safety, for example, enables crews to conduct JHAs prior to high-risk work, track certifications via QR codes linked to each employee, and standardize toolbox talks across projects. These practices not only satisfy inspectors but also foster stronger safety cultures by integrating documentation into everyday operations.

For companies using HCSS Safety, the advantages are measurable. Incident rates decline, Experience Modification Rates (EMR) improve, and insurance premiums reflect those safer records. Just as important, digital platforms create transparency, allowing leaders to identify trends and address risks proactively. When employees can see that their reports are acted on quickly and consistently, engagement rises and safety becomes part of the company identity.

Compliance as Strategy

The 2025 regulatory climate conveys a clear message: safety cannot be reactive. Contractors must integrate compliance into their daily workflows, build cultures that protect both physical and mental well-being, and prepare for audits at any moment. With penalties climbing and the Fatal Four expanding, there is no margin for outdated, paper-based approaches.

Digital tools offer a way forward, enabling contractors to simplify record-keeping, protect workers, and prevent costly interruptions. By centralizing data and creating audit-ready records, these platforms help companies meet evolving standards while maintaining productivity. In a year where the cost of non-compliance can derail entire projects, the smartest investment a contractor can make is one that ensures safety is consistent, transparent, and demonstrable.

Compliance, in other words, has become a business strategy as much as a regulatory necessity, and OSHA recordkeeping software is at the center of that transformation.